Posted by Dwight Lindsey on Apr 15th 2017

How Flat is Flat . . . and why should we care?

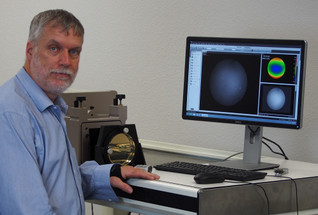

Our Zygo Interferometer

I'm sitting today with our new-to-us Zygo Phase Shift Interferometer, which we bought recently to check and control the flatness of the filters we manufacture and sell.

It's a very cool machine. Just impressive in every way.

As I waited for the air to fill the vibration isolation table (also a very cool device) I reflected on the reason we have this amazing instrument.

We are expending a great deal of expense and effort to make sure that our filters are very flat . . . so we should explain a bit why you as a user should care about that.

Here's Why We Care

Filters in an imaging system will affect the image in various ways. Sometimes this is desirable. Other times, not so much.

In today's digital world, we use fewer filter types than we did in the days of film. Commonly, we will use clear filters to protect our lenses, neutral density filters to give us creative control of depth of field, polarizing filters to reduce reflection and pump color saturation, and neutral density graduated filters to balance light levels across a scene. All of those filter types can have useful and desirable effects on the image.

The Problem

But many filters, particularly cheaper ones, come a problem: They're not absolutely flat. Filters used for cinematography need to be as flat as possible, to avoid reducing image quality in unwanted ways.

A filter that is curved in some way will impact image quality, usually reducing image quality. A filter can have a curvature that is spherical, cylindrical, toroidal or irregular. Filters can also have a "wedge" shape, where the surfaces are not parallel.

The Solution

What we want is for our filters to be quite flat, with plano-parallel surfaces. The surfaces should not be significantly curved or wedged. That's because a filter that is curved can and usually will reduce the quality of an image.

A very slight spherical curvature can be acceptable. A spherical curvature will have "power", which will change the focus point of a lens very slightly, but we can re-focus through that. Irregularly curved surfaces, or surfaces that aren't parallel (wedge), will reduce image quality in various ways throughout an image.

So how do we prevent this? We grind and polish our filters carefully to be extremely flat. Then we use a device called a laser interferometer to check the flatness of our filters quite precisely. The best laser interferometers in our industry are made by Zygo. When intelligently utilized, these instruments can precisely measure flatness (or lack of it) to fractions of a wavelength of light.

Here is an image which we made on the Zygo, showing one of our filters where the "transmitted wavefront" departs from flat by less than 1/2 of a wavelength of light, Peak to Valley. Much of that curvature is at the extreme edges of the filter. Tthe RMS value is a more useful measure and in the upper left of the image you'll see the RMS value of 1/10 of a wavelength. This is a very good filter. Even the peak to valley curvature of 1/2 wavelength is about 0.00001 of an inch. That is a supremely flat filter which will not disturb image quality in any way even with long focal length lenses..

The image on the bottom is the live display of "fringes" from the Zygo. The colored image on the top is the measurement data, displayed graphically and numerically. Notice the bowl shape of the wavefront, that is an amplified exaggerated view. This filter is so flat that you wouldn't be able to see the curvature in the image if it wasn't exaggerated.

Note the numeric

measurement at the top left of the image. PV 0.417 λ . Translated, this

means: Peak to valley = 0.417 wavelengths of light.

In case you're wondering, that is really, really flat.

We do try.

Next we should talk about anti-reflection coating . . .

Dwight